Bypass installed by means of pipe freezing

A modern office district was built in Hamburg with the City Nord at the end of the 1960s. In order to the building with air conditioning, the “Fernkälte Geschäftsstadt Nord GbR” was founded being the first German district cooling plant.

Demanding order for the Marx engineering office: pipe freezing in Hamburg City North

Operations manager Hans Weyerstall: “Our ring line for district cooling through the City Nord is twelve kilometres long and has three lines, to which the 17 shareholders are connected.” One of the most distinctive buildings of the City Nord, the former postal check office – also popularly known as the Post Pyramid – is being demolished since July. Modern office and residential buildings will be created in its place, the so-called “Ipanema Project”. Operations manager Hans Weyerstall: “The postal check office was supplied with district cooling by line number 3. Due to the demolition, now we had to install a bypass around the supply line affected. We could not simply disconnect the line for a few days. As the other customers on line 3, amongst other the DEA still need cold around the clock, primarily for the IT systems.” As there are no gate valves installed in the lines, Weyerstall and his employees relied on the pipe freezing process. Weyerstall: “On the left and right side of the supply line to the old postal check office, we excavated one pit each and mounted two freezing collars each locally around the two water-bearing pipes (diameter 500 mm).” Then -196° cold nitrogen (LN2) was filled into the collars – with the result being that the water freezing completely after eight hours. Weyerstall: “Now we could open the valves in the bypass previously installed and the problem was solved.”

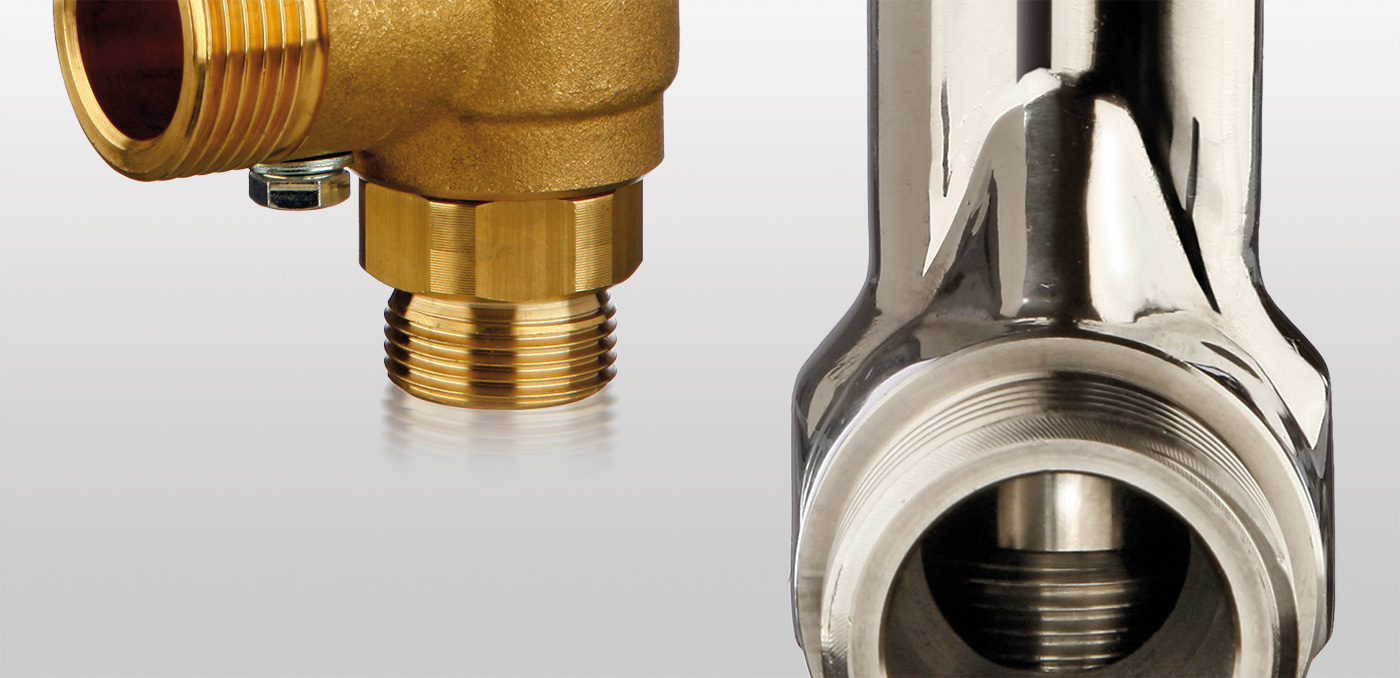

Pipe freezing is a domain of the engineering office Marx from the Brandenburg town Ahrensfelde, that has specialised in low temperature technology and gas applications. They were instructed by the Fernkälte Geschäftsstadt Nord GbR for this project at the end of 2016. Owner Bodo Marx: “We had to keep to a tight time frame.” According to the engineering office, the collars for the nitrogen with a length up to 1.5 m were made of stainless steel. The nitrogen tank had a volume of about 15,000 litres, safety valves and gate valves from HEROSE were used. The engineering office Marx and the company from Bad Oldesloe have been working together for more than five years where, in the mean time, the relationship goes far beyond a pure customer/supplier relationship. Bodo Marx runs seminars in Bad Oldesloe for the subject area cryogenic liquefaction at regular intervals.