LNG barge – a floating powerstation

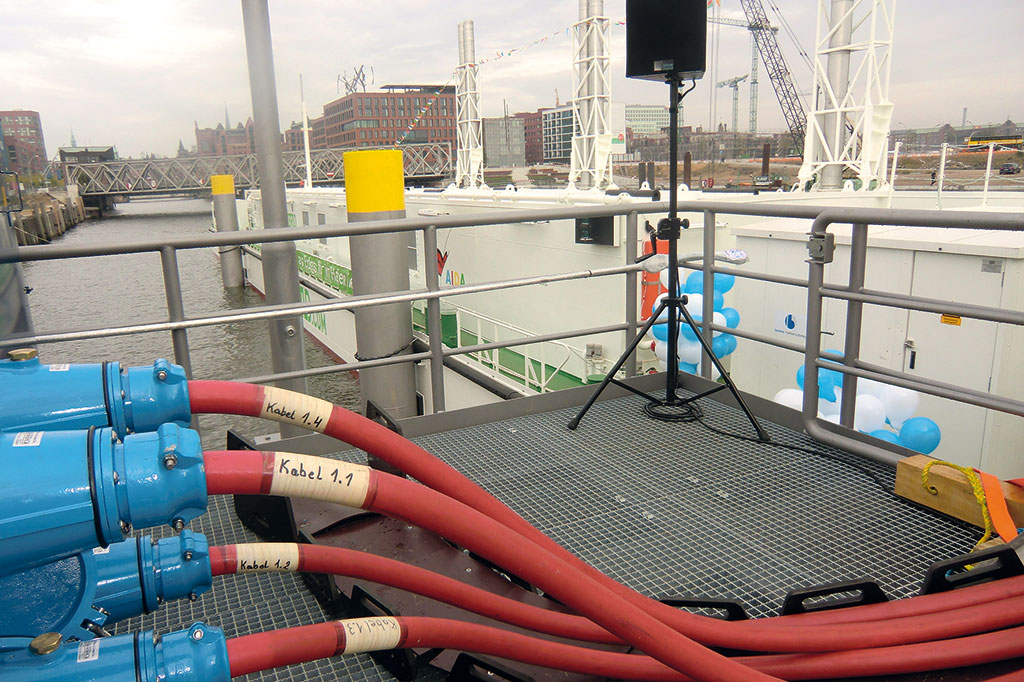

The first floating liquid gas power station in a German harbour has been christened mid-October with the name of “Hummel”. The LNG-Barge by Becker Marine Systems – approximately 77 metres long and eleven metres wide – is equipped with five generators producing a total output of 7.5 megawatt. These are to supply the AIDA cruise ships in Hamburg harbour with energy during the next season. HEROSE contributed with extensive supplies to the new construction.

Because a new LNG barge with HEROSE valves supplies AIDAsol with power after it docked at the Hamburg harbour city, the cruise ship can shut down its Diesel from 2015. This contributes to both environmental and climate protection

During the launch ceremony a connection between the barge and the cruise ship AIDAsol, which entered Hamburg harbour for the last time this year on that day, was made for the first time. According to AIDA president Michael Ungerer the pilot project was “a signal for environmental and climate protection – not only for Hamburg, but for the entire maritime industry”. The AIDA cruise ships mooring in the harbour city can shut down their Diesel generators in the harbour from the next season and obtain their power from environmentally friendly liquified natural gas. LNG does not generate sulphur dioxide or carbon particles; the emission of nitrogen oxides and CO2 is significantly reduced.

The cryogenic liquefied natural gas arrives by truck from Rotterdam and is then transferred directly as a module to the barge. A LNG bunker station can be expected in Hamburg during 2016 at the earliest. The following are of interest in this context: The Brunsbüttels harbour industry and its regional industry have recently also registered an interest in building an LNG import terminal. This could also benefit Hamburg harbour.

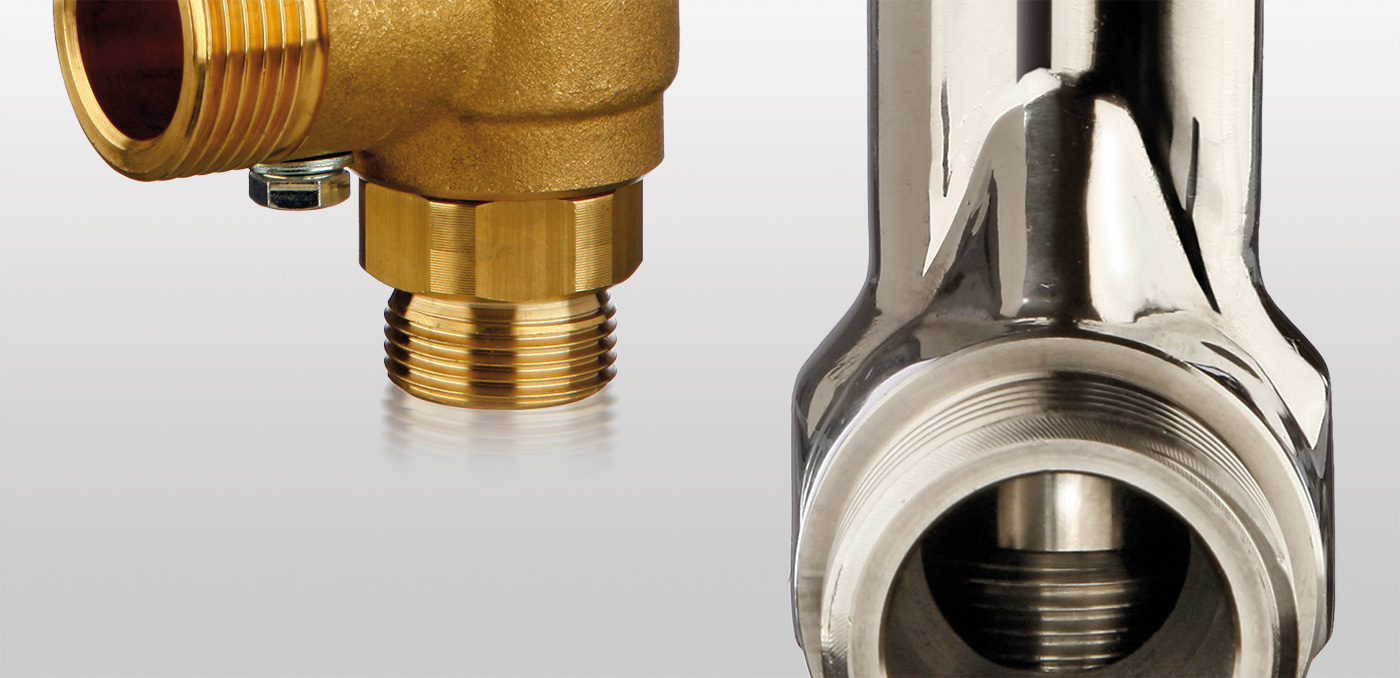

The LNG-barge was built in a shipyard in Slovakia and arrived in Hamburg harbour early October after a three week journey via the Danube, Main, Rhine, the North Sea and the Elbe. The Czech company Chart Ferox was responsible for the container construction. HEROSE supplied it with various globe valves. The product portfolio ranged from manual shut-off valves to pneumatically actuated valves with comprehensive accessories. HEROSE managing director Zschalich: “This was a demanding order. Not only did various production particularities have to be taken into account, but the time pressure was also immense.”

The following conditions had to be considered for the valves for the LNG-Barge: The valves had to be adapted to the operating conditions (technical adaptations). Further required were special limit switches and special aluminium cabinets. The valves had to be sea water resistant and fire-safe in accordance with EN ISO 10497, the accessories had to be specially coated. Specific casting was produced because the casting process had to be monitored and certified by the classification society Bureau Veritas (BV). The control valve was newly developed. And the delivery time was only ten weeks.

The LNG-Barge concept is not only of interest to sea harbours. It can also be utilised on rivers, for example at water construction sites or harbours. “We see excellent prospects for our technology, because environmental awareness is continually increasing, leading to stricter national and global regulations for the protection of people and the environment”, said Dirk Lehmann, managing director of Becker Marine Systems.

Liquefied natural gas is beginning a versatile use for shipping. In Scandinavia ferries already operate with LNG as fuel for the main engine – HEROSE supplied various valves for construction of these ships (report by vc). Becker Marine Systems plans container feeder ships with natural gas drives in the Baltic Sea in the future. The Hamburg shipping company Hansa Treuhand also has a similar concept in hand according to its founder and owner Hermann Ebel. And Björn Rosengren, CEO of the Finnish corporation Wärtsila, a leading manufacturer of ship engines and a client of HEROSE, recently stated on the SMM exhibition in Hamburg: “Today about 50 ships with natural gas drives operated globally; in 2020 this number might already be 1200 or 1300.”

HEROSE Valves for LNG use

Cryogenic globe valve type 01841

Cryogenic globe valve with pneumatic actuator type 01843

Cryogenic globe valve type 01851

Cryogenic globe valve with pneumatic actuator type 01853

Photos: Becker Marine Systems, Carsten Wurr