Steam is used in almost all areas of industrial production as a source of energy and as a carrier of chemical substances. Above all, high temperatures are an issue and can lead to hazards. We secure so that you can work safely.

"A steam engine without a safety valve is like a car without brakes."

Steam

in action:

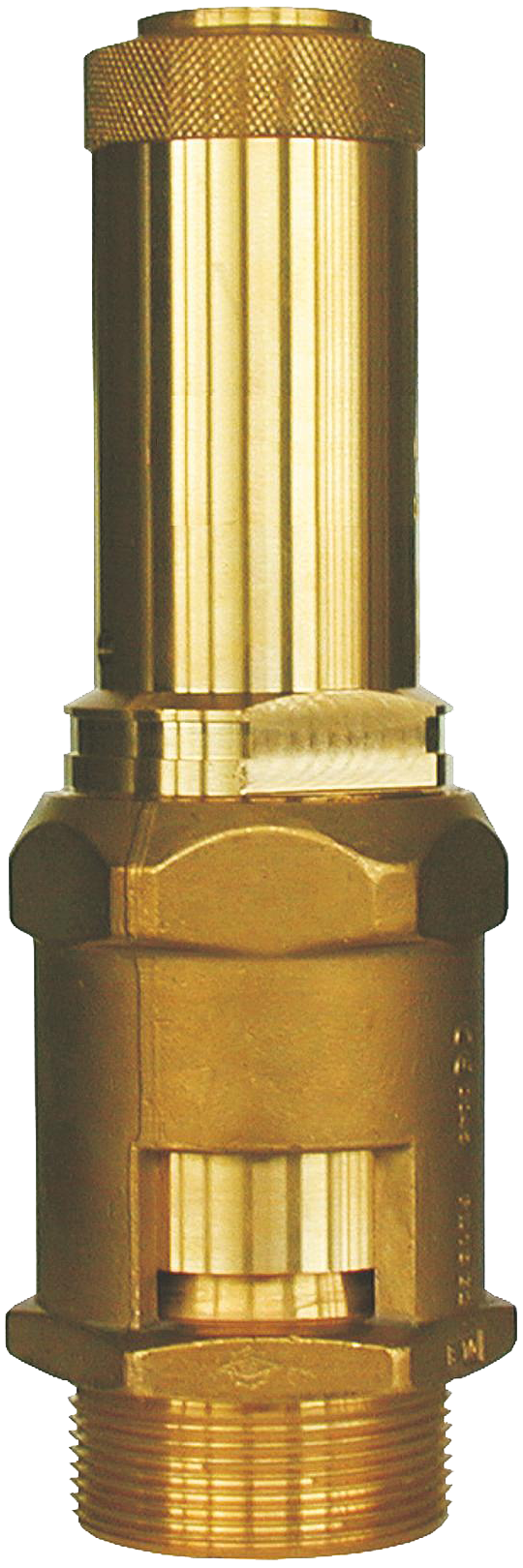

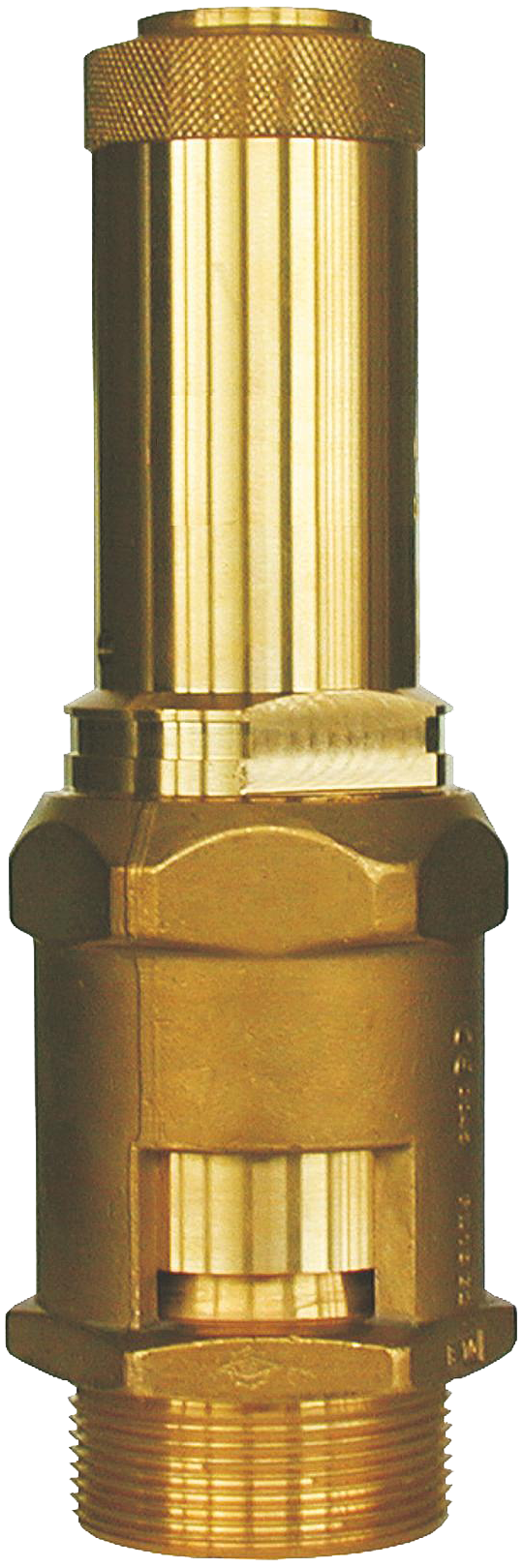

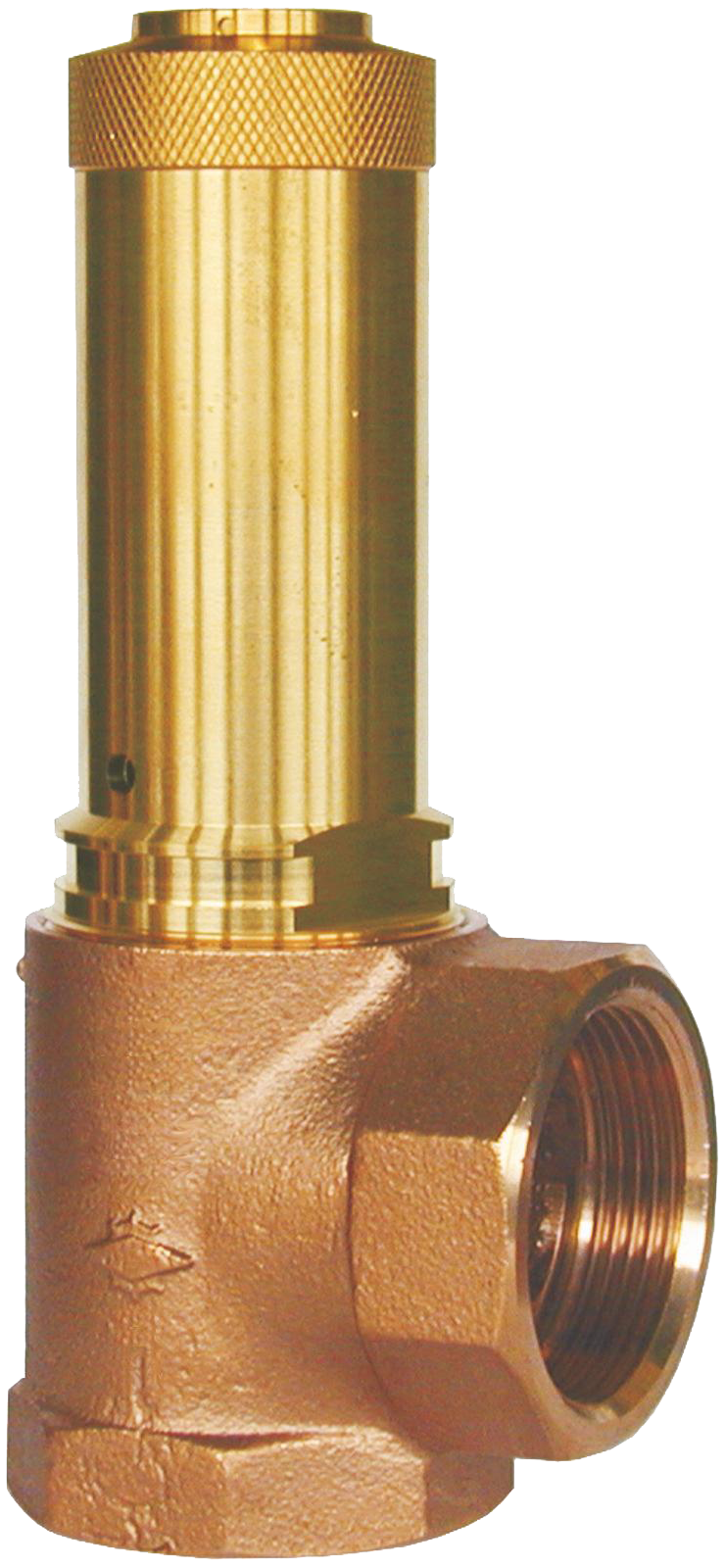

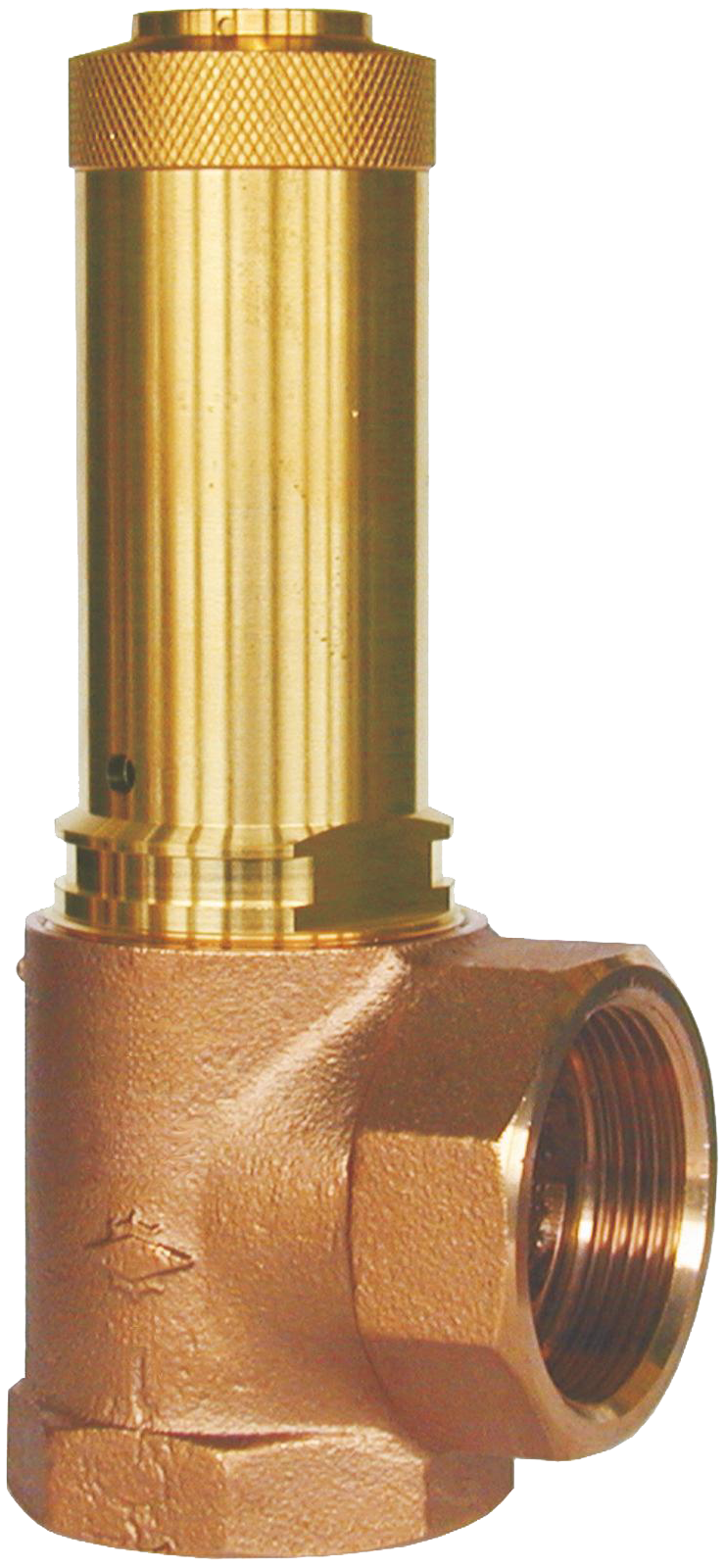

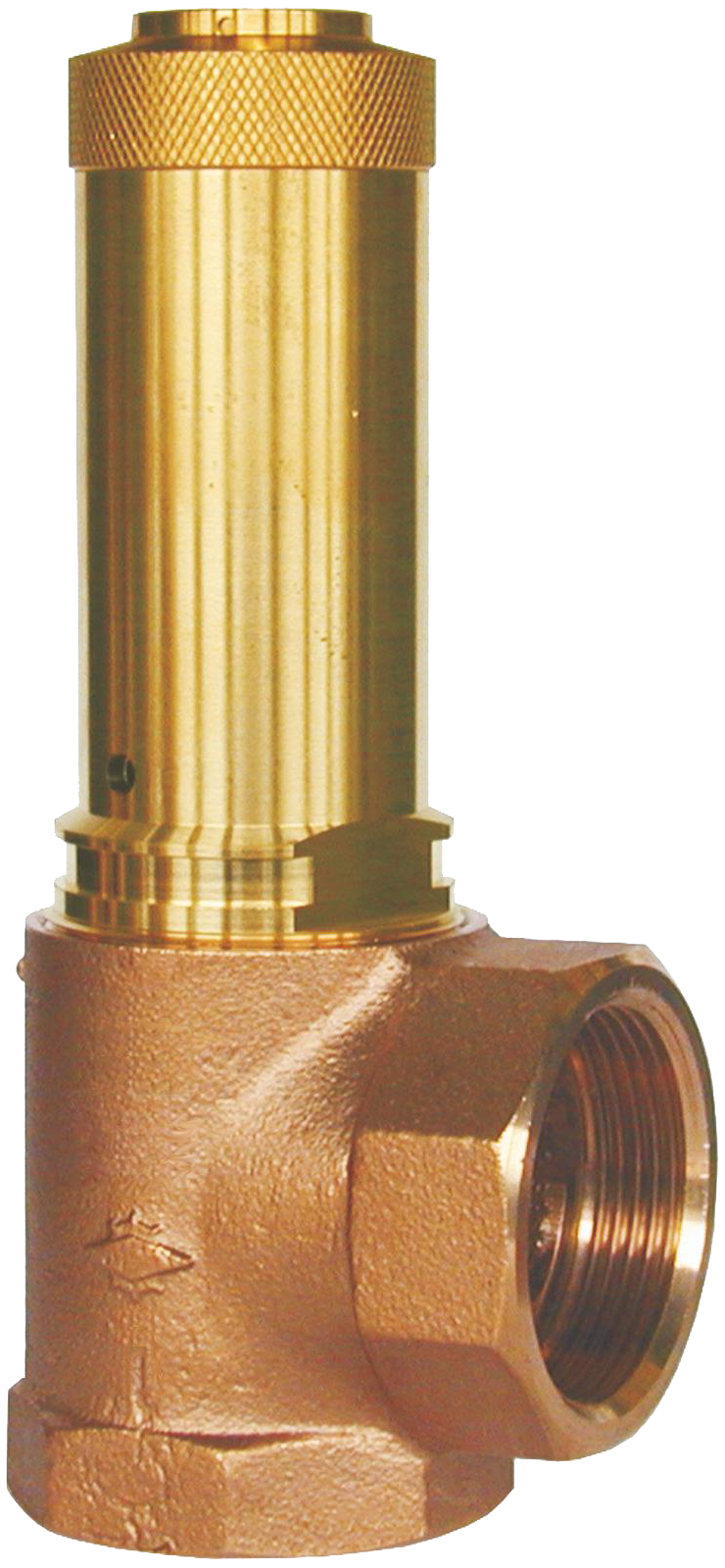

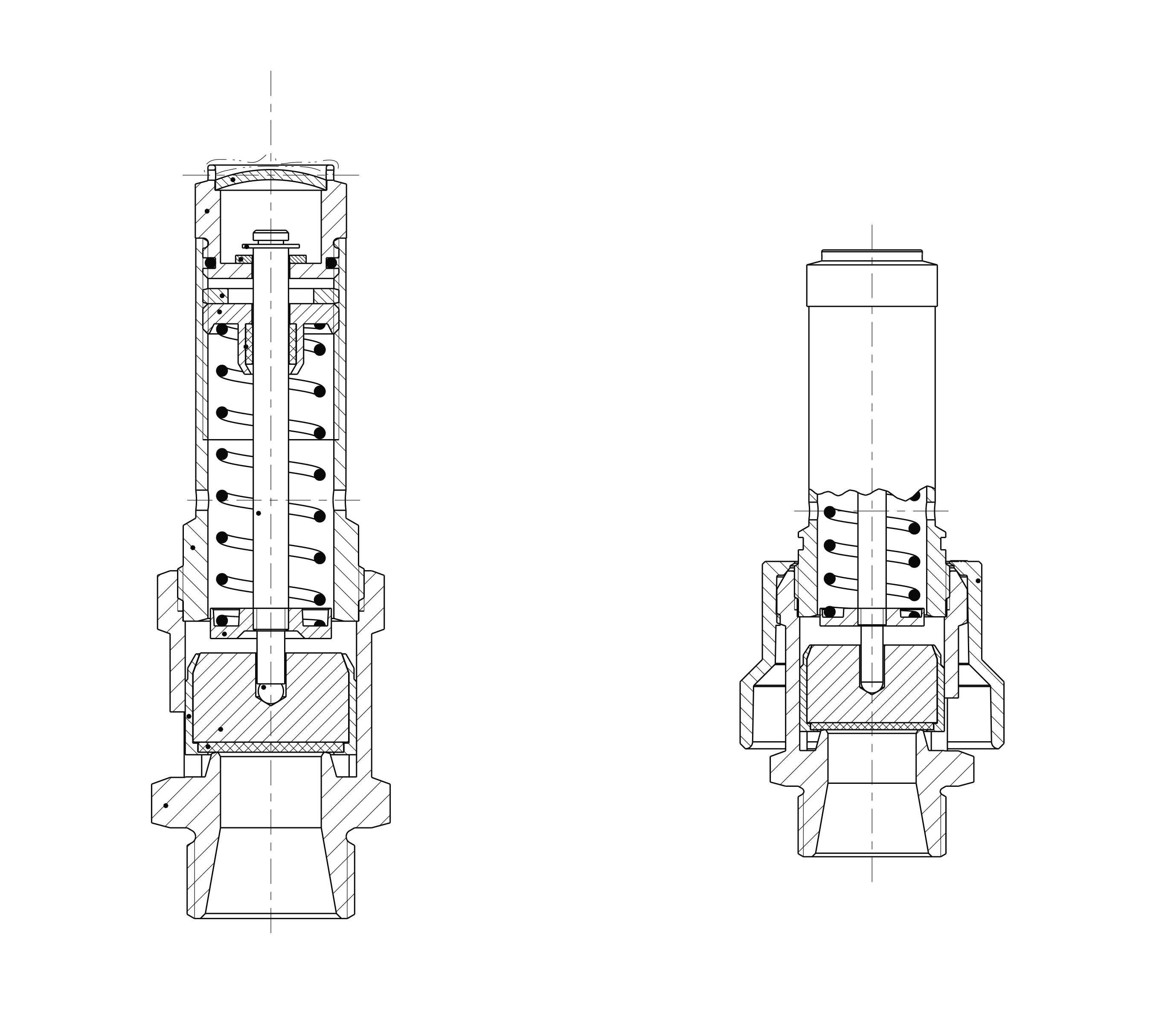

- In the many steam applications, dangerous situations can arise for people and machines due to sudden increases in pressure. In order to avoid this and safely blow off excess pressure, the components should be carefully selected in order to safely discharge the hot medium.

- We use high-quality materials to reliably protect your steam system or steam boiler from overpressure. All safety valves that leave our site are adjusted, tested and sealed to ensure safe and economical operation of the processes.

- Typical applications are sterilizers and autoclaves where the steam is used for sterilization. But our solutions also ensure the protection of the cooking kettles in canteen kitchens.

- Liquids can be separated with the addition of heat using a distillation process. An important criterion is the surface quality of the materials used. Depending on the area of application and the type of sealing material, HEROSE offers the use of stainless steel springs and the option of nickel-plating the vlves. This is mainly used in medical areas and in the chemical industry, e.g. in distillation systems, sterilizers and autoclaves.

We offer solutions for these areas:

-

Sterilizers & Autoclaves

Sterilizers and autoclaves are used primarily in the medical and pharmaceutical sectors.

-

Distillation plants

In the food and beverage industry in particular, there are many applications that require reliable protection.

-

Propulsion of ships

In addition to the types of propulsion known today, there is still the classic steam propulsion.

Wiki Base

Did you know?

Where a mistake has far-reaching consequences, we are the obvious solution.

Depending on the area of application and the type of sealing material, HEROSE offers the use of stainless steel springs and the option of nickel-plating the fittings. This is mainly used in medical areas and in the chemical industry, e.g. sterilizers and autoclaves.

With our valves, everything revolves around one thing: your needs.

Liquids can be separated with the addition of heat using a distillation process. An important criterion is the surface quality of the materials used. We offer you a wide range specifically tailored to your needs.

Anyone with a lot of experience does not shy away from a challenge.

Steam-powered ships are a rarity these days, so standard valves are not an option. However, we at HEROSE will find a suitable solution for every application.